NdFeB magnets

Review

Description

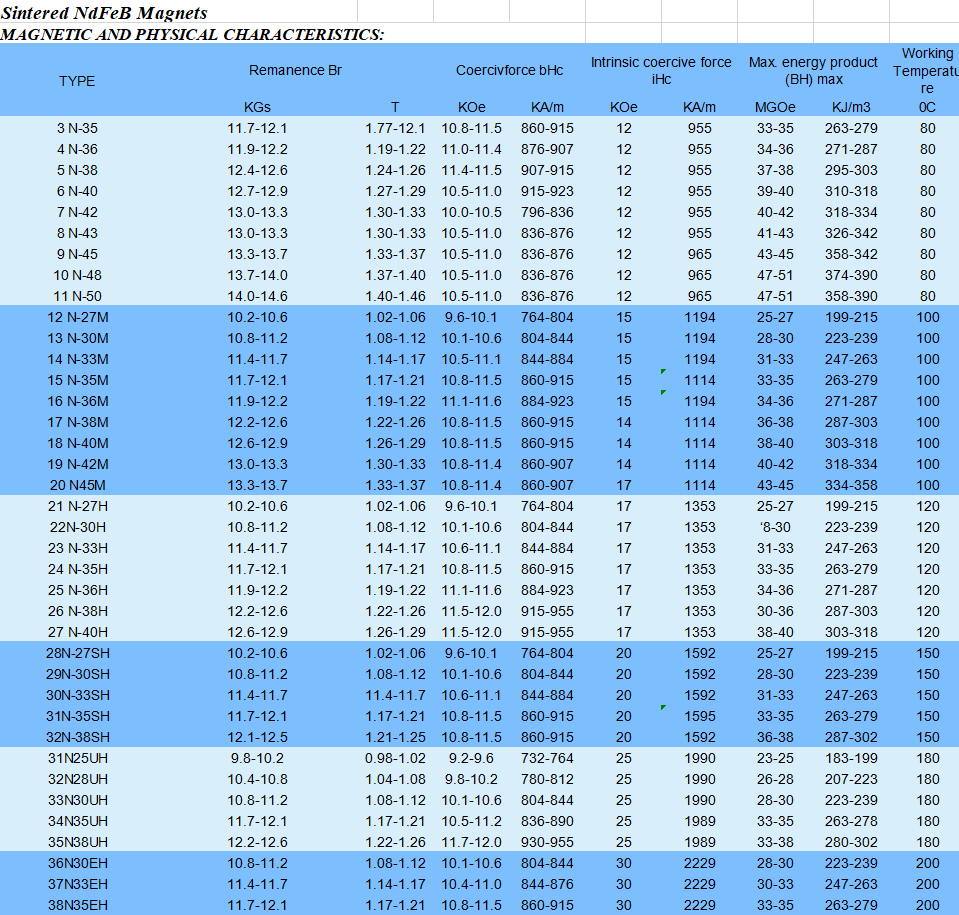

NdFeB(Neodymium-Iron-Boron) magnet is used most popular by people in industry and our daily life, because it has superior magnetic properties than other kind of magnets. The outstanding characteristics are as follows--------

·Higher unit magnetic properties than other magnet and assure you of smaller size and lighter weight in designing devices.

·Being mostly an iron based alloy, NdFeB type rare earth magnet is much more prone to surface oxidation or rust. To eliminate such a problem, the user should consider magnet coating, plating, or suitable surface treatment.

·Being less prone to chipping during handing

·Lower temperature coefficient of magnetic properties than ceramic but higher than SmCo type rare earth magnet. Therefore, this NdFeB type rare earth magnet will suffer irreversible loss at high temperature.

The permanent magnets, which are called the next centurial magnets, are used in a wide range of industries including computer, automobile, electric machinary, electro-sound devices, automatic control, magnetic force mechanism, microwave commnication, petrochemical industry, medical apparatus and equipment. The magnets are the ideal materials for the subminiature magnetic devices with high function.NdFeB magnets is especially suitable for developing those new products demanding high quality, small volume and light weight.

Surface Treatment Method:

| Type | Information |

|---|---|

| Metallic | Zinc,Nickel,Nickel+Nickel,Copper+Nickel,Nickel+Copper+Nickel,Gold |

| Organic | Epoxy,Nickel+Epoxy coating |

| Temporary | Surface Pssivation |

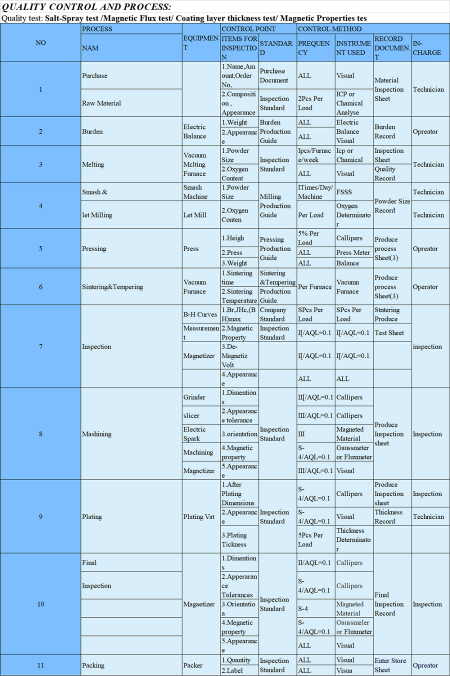

Produce Flow Chart: |  |

|---|

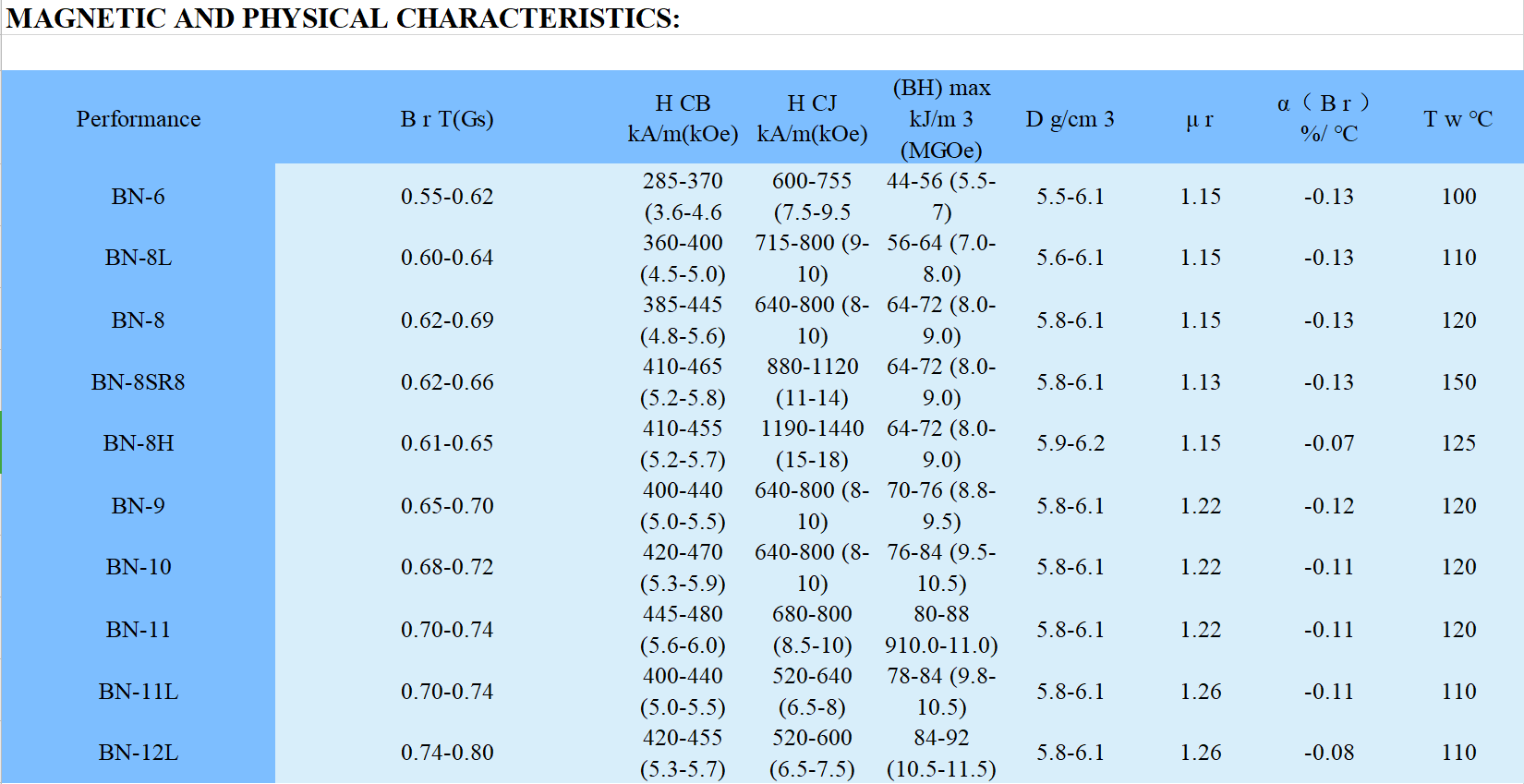

Bonded NdFeB Magnets

Bonded NdFeB magnets are manufactured by binding rapid-quenching NdFeB powder. The powder is mixed with resin to form a magnet by compression molding with epoxy or infection molding with nylon. The latter technique is particular effective in large volume production, though the magnetic value of products is lower than lower than those made with compression molding because of their relatively lower density. Various shapes of high dimensional accuracy can be produced without further processing. Surface is treated by epoxy coating or nickel-plating to prevent corrosion .

Advantages of Bonded Magnets

·Produced with high efficiency, stability and repeatability.

·Magnet and other part may form together in one step.

· Free choice of magnetizing direction-especially for multi-polar applications

· High dimensional accuracy-large quantity applications with minimum post-press machining.

· Thin-wall ring and complex shape magnets.

· High resistance to corrosion.