Alnico Magnet

Review

Description

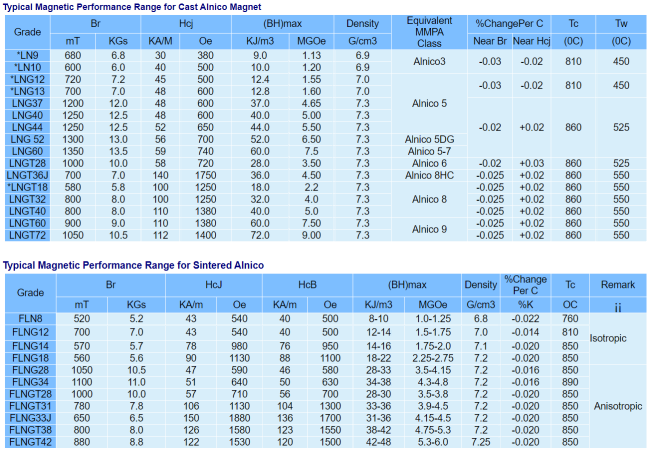

Specialized casting techniques are used to achieve the unique crystalline grain orientation found in the Alnico 5 and 8 grades. These anisotropic grades are designed to produce high magnetic output in a specified direction. Orientation is achieved during heat treatment, by cooling the casting from 2000?F at a controlled rate within a magnetic field which conforms to the preferred direction of magnetization. Alnico 5 and Alnico 8 are anisotropic and exhibit a preferred direction of orientation.

Magnetic orientation should be specified on your drawing when you send an order to us. Cast Alnico 5 is the most commonly used of all the cast Alnicos. It combines high inductions with a high energy product of 5 MGOe or more and is used extensively in rotating machinery, communications, meters and instruments, sensing devices and holding applications. The higher resistance to demagnetization (coercive force) of Alnico 8, cobalt content to 35%, allows this material to function well for short lengths or for length to diameter ratios of less than 2 to 1.

Sintered Alnico materials offer slightly lower magnetic properties but better mechanical characteristics than the cast Alnico materials. Sintered Alnico magnets are most suitable in small sizes (less than 1 oz.). In this process, the desired mix of metal powders is pressed to shape and size in a die, then sintered at 2300?F in a hydrogen atmosphere. The sintering process is well suited to large volume production, and results in parts which are structurally stronger than cast magnets. Relatively close tolerances can be achieved without grinding.